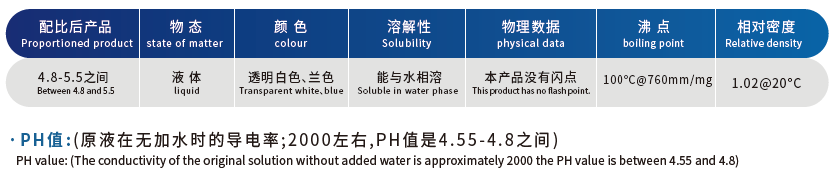

配比在2%左右时导电率为1000左右,PH值4.8-5.5之间。

When the ratio is about 2%, the conductivity is about 1000, and the PH value is between 4.8 and 5.5.

配比在3.5%左右时的导电率为1470左右,PH值4.8-5.5之间。

When the proportion is about 3.5%, the conductivity is about 1470, and the PH value is between 4.8 and 5.5.

配比在4%左右时导电率为1500左右,PH值4.8-5.5之间。

When the ratio is about 4%, the conductivity is about 1500, and the PH value is between 4.8 and 5.5.

使用情况 Usage Situation

水箱温度应保持在10至15度,自来水的pH值影响较小,建议配比在2%-4%之间。该产品适用于所有平版印刷机品牌(如海德堡、小森、三菱等),起始配比为2.5%,若水质较硬可增加至3%-4%。包装有25L、200L和1吨桶,并可安装集中供水系统以自动配比,具体用量根据生产需求调整。

The temperature of the water tank should be maintained at 10 to 15 degrees, and the pH value of tap water has a small impact. It is recommended to proportionate in a ratio between 2% and 4%. This product is suitable for all sheetfed printing machine brands (such as Heidelberg, Komori, Mitsubishi, etc.), with a starting ratio of 2.5%. If the water quality is hard, it can be increased to 3% -4%. The packaging comes in 25L, 200L, and 1-ton drums, and can be equipped with a centralized water supply system for automatic proportioning. The specific amount can be adjusted according to production needs.

使用操作要求 Operation Requirements

在开印前,需根据无醇润版液和普通润版液的不同,调整印刷机的供水系统,包括确保上水辊平衡和适当设置计量辊压力。首先,检查并清洗上水辊、墨辊和橡皮布,切勿使用洗车水或汽油。调整不平衡的上水辊,避免单边干版。调整计量辊压力后,微调上水量。清空并彻底清洗水箱,保持温度在10度,建议每15-20个工作日清洗一次。准确计算水箱内总水量,均匀播入润版液后再倒入水中,补充时需按比例兑匀后再加入水箱,以免影响效果。

Before printing, it is necessary to adjust the water supply system of the printing machine according to the difference between non-alcoholic and regular fountain solutions, including ensuring the balance of the water supply roller and setting the pressure of the metering roller appropriately. Firstly, check and clean the water roller, ink roller, and rubber blanket, and do not use Ink cleaner water or gasoline. Adjust the unbalanced water roller to avoid single-sided dry plate. After adjusting the pressure of the measuring roller, fine tune the amount of water added. Empty and thoroughly clean the water tank, keeping the temperature at 10 degrees. It is recommended to clean it every 15-20 working days. Accurately calculate the total water volume in the water tank, evenly pour in the fountain solution before pouring it into the water. When replenishing, it is necessary to mix it in proportion before adding it to the water tank to avoid affecting the effect.

润版液是一种在印刷过程中用于保持印刷版面湿润和平衡油墨分布的酸性液体,一般呈现透明色。具有优异的润湿性,良好的稳定性和环保安全等特性。深圳阪田油墨有限公司提供的润版液种类主要有无醇润版液,环保型润版液热固型和环保型润版液冷固型,高效型润版液。

Fountain solution is an acidic liquid used during the printing process to keep the printing surface moist and balance ink distribution, generally presenting a transparent color. It has excellent wetting properties, good stability, and environmental safety characteristics. The types of fountain solutions provided by Shenzhen Bantian Ink Co., Ltd. mainly include non-alcoholic fountain solutions, environmentally friendly fountain solutions, Environmentally friendly fountain solution for heat set and cold set, and high-efficiency fountain solutions.